services

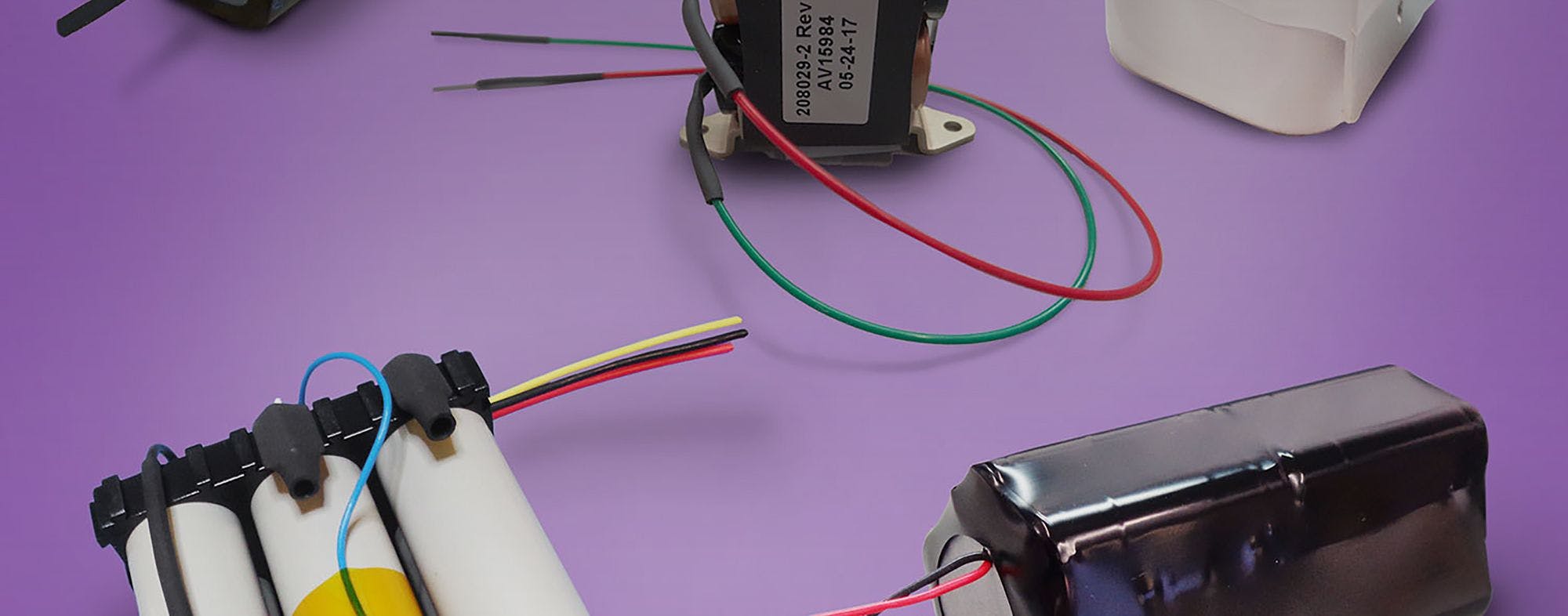

Battery packs, cables, and harnesses testing

Aved uses several Chroma 17020 high precision systems specifically designed for secondary battery modules and pack tests. Accurate sources and measurements ensure a level of test quality that is suitable for performing repetitive and reliable tests. This reliability is crucial for battery modules/packs, for both incoming and outgoing inspections, as well as capacity, performance, production, and qualification testing.

Aved uses a broad range of automated wire processing equipment for wire from 30 Ga to 1 KC mil and virtually any connector type. Featuring a 100% test of each cable assembly, we use Cirris® 1100R+ testers incorporated onto mobile carts with dedicated computers that store all test results including part numbers, customer information, serial numbers, and lot identification for each.

The enhanced testing capability provided includes building test fixtures and mating connectors for each cable assembly. With over 40 years of experience, we can help identify the optimum wiring and cable solution for virtually any application. There are 16 mobile carts available to perform complete testing including SPC to validate testing quality.

Aved’s dedicated Electrical Engineering department will develop appropriate tests for each specific design released into our production cycle. Output documentation and record retention with serialized control are the new standard for battery production efforts.

Include:

- Product validation and verification testing

- Customer use case modeling through Chroma 17020 Battery Systems

- Cell Impedance matching and quality control